To understand the benefits of 3D printing, you need to know your alternatives. The most common form of plastic production today is called injection molding, and this has been around for a while. It is why we think of large-scale production using plastic, things like water bottles and gas cans. These items work well when using injection molding, and factories can churn out many of these items. Unfortunately, this process does not leave a whole lot of room for creativity.

At HWB Prints in Dallas, TX, we understand the importance of customization, and 3D printing brings you more power than ever before. Additive manufacturing builds 3-dimensional items from a digital design file, building the product layer by layer. This gives you the ability to make items that are more your style, helping you to create custom plastic objects without the expense or hassle of traditional injection molding. When you want to make something truly special, talk to our team about your options. Give us a call today to learn more!

Injection Molding Is Made For Mass Production

Traditional methods of plastic production were designed for bulk creation, not specialized projects. This is why we see them for coolers and luggage, because they are things that can be produced in mass amounts. These are created using a process called injection molding, and it is the most common form of plastic production. This method uses a molten material that hardens into a shape, and there is a wide range of applications for this process.

While injection molding has its advantages, it is not suited for every project. Ones that require a little extra thought, especially ones with a need for customization, can benefit from a different approach. With 3D printing, you can bring your designs to life, all through the use of a digital file.

3D Printing Gives You More Custom Options

When you want to design something that is truly special, 3D printing gives you the options that you need. This process operates a little differently than injection molding, and you can use these advantages to your benefit.

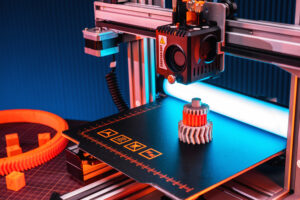

With 3D printing, your items are built through thin layers of an applied plastic. These designs are printed from computer aided design (CAD) files, giving you the opportunity to send your next project over to us from anywhere on the planet. As these layers build up, they create your custom item from the base up. 3D printing can even be used to make items of any size, as we can build in sections.

Learn More About 3D Printing Today!

If you are looking to make something truly unique for your home or office, talk to our team today. Give us a call at HWB Prints in Dallas, TX at (469)783-6865 or email us at Info@hwbprints.com!